High speed metal eyelet stamping production line

I. Main features

Application: shoes, bags, garments, curtains, canvas etc.

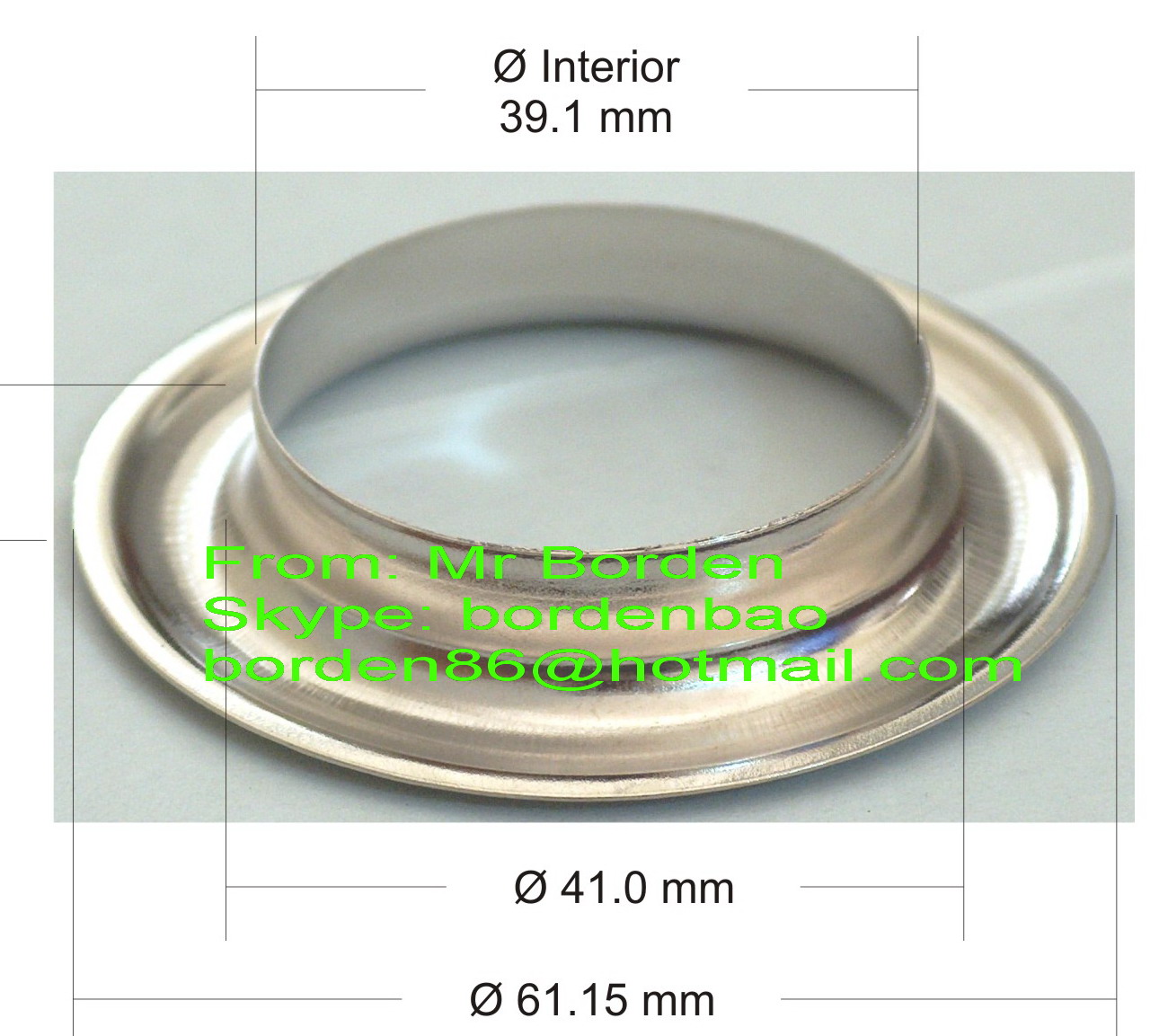

Material: steel, brass, aluminum etc.

High speed: 150-250 strokes per minute.

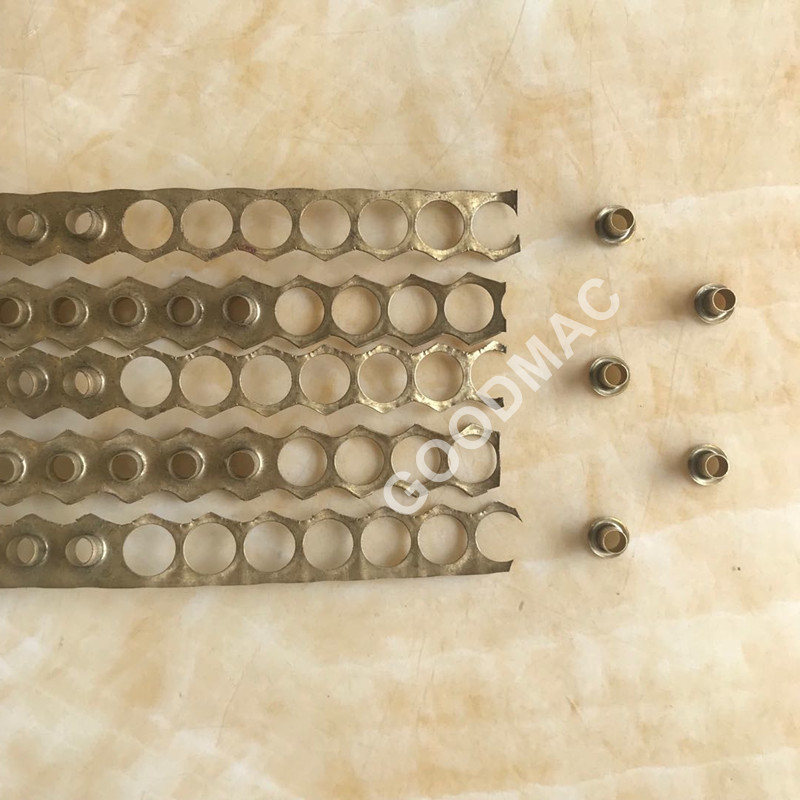

1 cavitity mold can produce 1 piece of eyelet per stroke.

2 cavities mold can produce 2 pieces of eyelets per stroke.

3 cavities mold can produce 3 pieces of eyelets per stroke.

4 cavities mold can produce 4 pieces of eyelets per stroke.

5 cavities mold can produce 5 pieces of eyelets per stroke.

6 cavities mold can produce 6 pieces of eyelets per stroke.

7 cavities mold can produce 7 pieces of eyelets per stroke.

II. An full automatic high speed metal eyelet stamping production line includes below basic machines.

A pallet type decoiler.

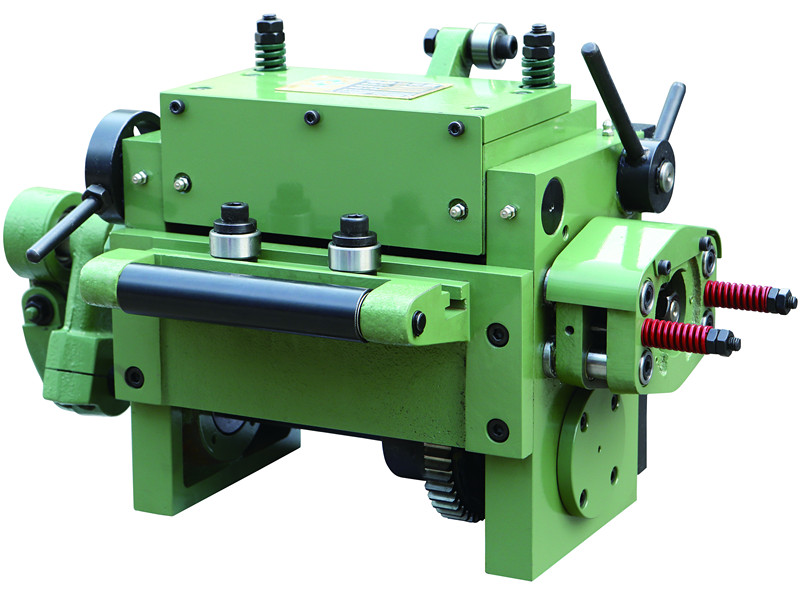

A high speed mechanical roll feeder.

A 25tons C frame high speed precise press machine.

or a 45tons C frame high speed precise press machine.

or a 65tons C frame high speed precise press machine.

III. Process

1. The decoiler can decoil the metal sheet coil automatically.

2. The high speed mechanical roll feeder can clamp and feed the metal sheet forward to the press machine automatically.

3. The high speed precise press machine can press with its slide automatically.

4. The stamping molds can press and form for the metal sheet automatically.

If you want to buy and use compact cheap low speed press machine to produce prong snap buttons, we can recommend and supply them for you also.