High speed prong snap button stamping production line

I. Main features

Application: garments, bags, garments, curtains, canvas etc.

Material: steel, brass etc.

Size: 9.5mm, or 12.5mm, or as per your samples or drawing

High speed: 150-250 strokes per minute.

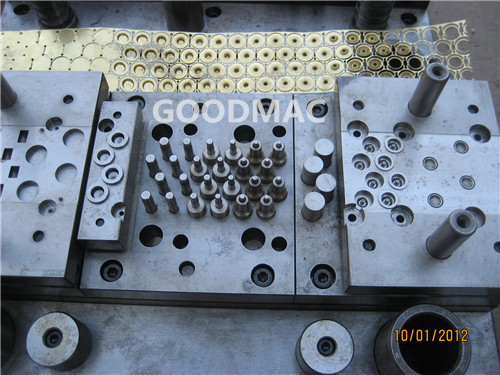

Snap cavity, 3, or 4, or 5, or 6, or 7.

Stud cavity, 3 or 4, or 5, or 6, or 7.

Socket cavity, 3 or 4, or 5, or 6, or 7.

1 cavity mold can produce 1 piece of product per stroke.

2 cavities mold can produce 2 pieces of products per stroke.

3 cavities mold can produce 3 pieces of products per stroke.

4 cavities mold can produce 4 pieces of products per stroke.

5 cavities mold can produce 5 pieces of products per stroke.

6 cavities mold can produce 6 pieces of products per stroke.

7 cavities mold can produce 7 pieces of products per stroke.

II. An full automatic high speed prong snap button stamping production line includes below three basic machines.

A pallet type decoiler.

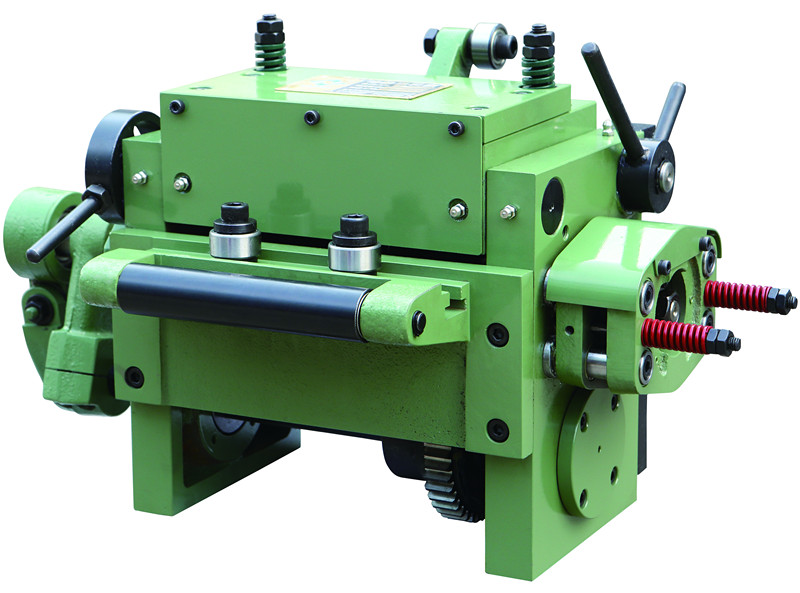

A high speed mechanical roll feeder.

A 25tons C frame high speed precise press machine.

or a 45tons C frame high speed precise press machine.

or a 65tons C frame high speed precise press machine.