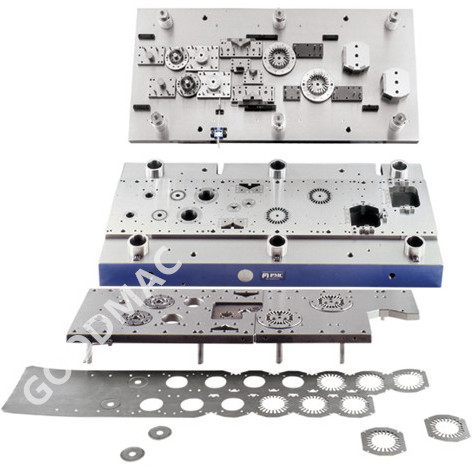

High speed electrical motor stator and rotor lamination stamping production lines

Applicable steel sheet material: silicon steel.

Applicable steel sheet coil width: as per your various widths.

Application: electrical motor stator and rotor lamination stamping.

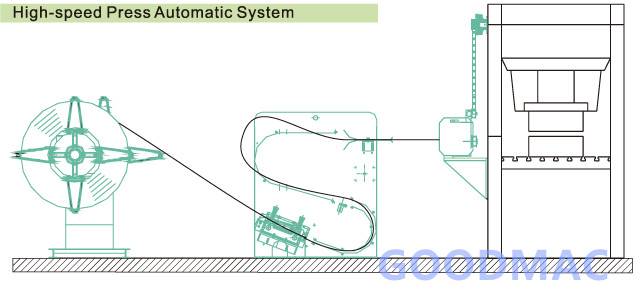

When your steel sheet coil width is not over than 500mm, we can supply below various high speed feeding lines to you.

Double side decoiler (model MTD series, or MTDM series, or DMTD series)

High speed S loop straightener (model TUS series)

High speed cam gear feeder (model GCF series)

Or high speed NC single servo roll feeder (model GCD series)

Or High speed NC double servo roll feeder (model GCH series, a servo motor for feeding, another servo motor for pilot releasing.)

Double side high speed hydraulic motorized decoiler (model DMHD series)

High speed S loop straightener (model DTHS series)

High speed NC double servo roll feeder (model GCH series, a servo motor for feeding, another servo motor for pilot releasing.)

When your steel sheet coil width is very wide, such as 600mm or 650mm or 700mm, thickness is thin, such as 0.25mm only,

we can supply below high speed feeding-pulling line to you.

Motorized hydraulic decoiler (single side decoiler, or double side decoiler.)

High speed S loop straightener, model DTHS-600

High speed NC double servo roll feeder, model SGCH-600 (first feeder feeds steel sheet forward, second feeder pulls the steel sheet out easily.)

High speed servo shearing machine (to cut scrap strip after stamping).