I. Main feature

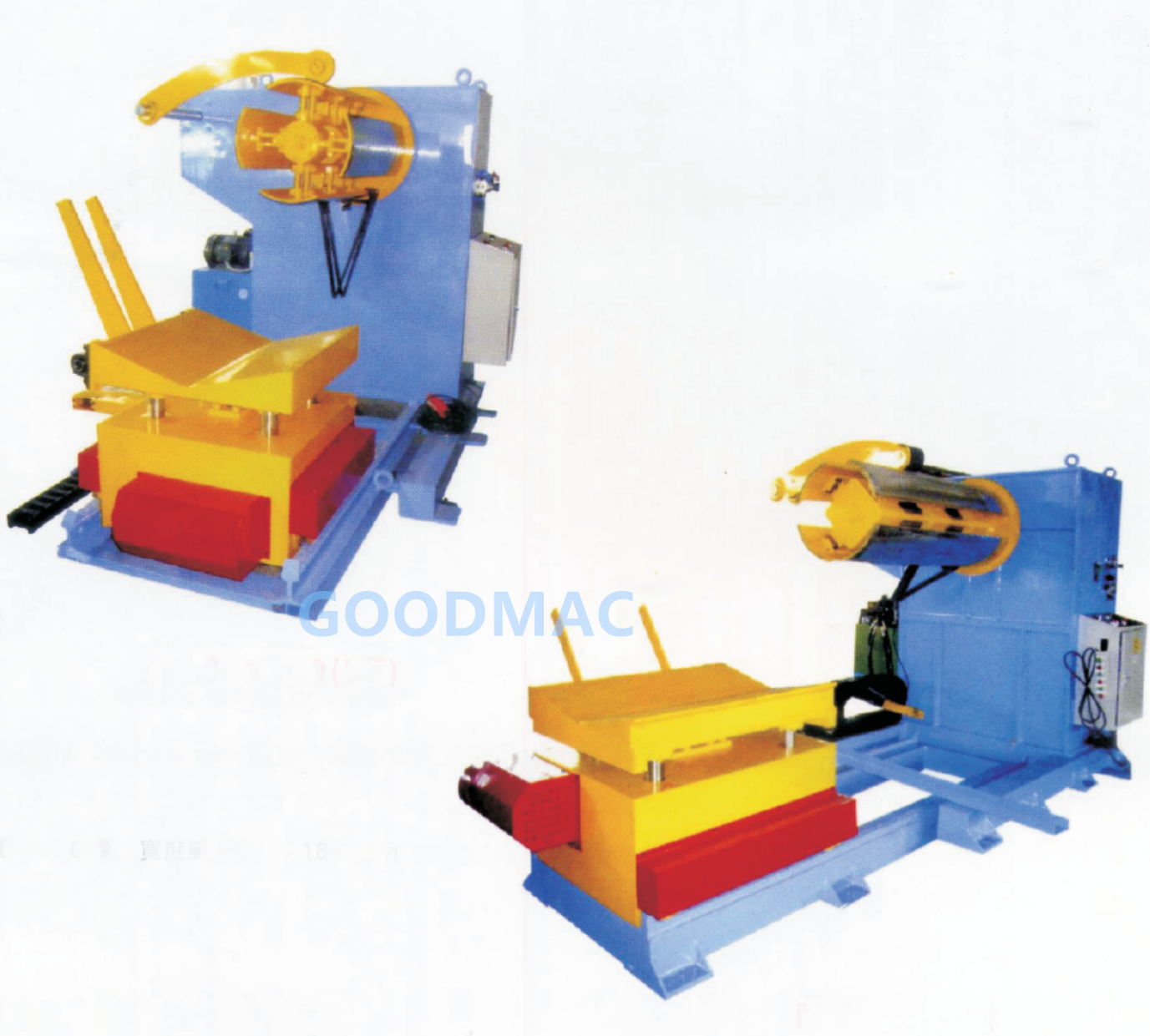

1. These MT-H series high quality decoilers are very regular decoiling equipment for automatic metal sheet stamping industry mainly.

2. They can suit for various metal sheet material, such as cold rolled steel, hot rolled steel, galvanized steel, silicone steel etc.

3. Each decoiler adopts a good quality design, with strong cantilever mandrel and base structure, to load a heavy metal sheet coil.

4. It adopts high quality components, for long service life and low malfunction.

5. Its mandrel can expand and shrink automatically, thought a hydraulic cylinder and hydraulic system.

6. A pneumatic holding down device is equipped to press the metal sheet coil and prevent the coil loosing. It can rise or press down automatically through a pneumatic cylinder drive.

7. It has an additional supporting stand, which can support the mandrel shaft, in order to help the decoiler to load heavy metal sheet coil. It can open or close by a manual adjusting mechanism device.

8. It has an automatic pneumatic disc brake device. so can stop decoiling smoothly.

9. A removable controller can be equipped for users to operate the decoiler easily.

10. An inverter is equipped to adjust variable decoiling speed easily.

11. It has an electronic sensor rack, for metal sheet touching and automatic loop control.

12. The hydraulic system includes oil container, motor, valves, switch, pipe, etc.

13. A coil car can be equipped as optional, for loading a heavy coil to the decoiler mandrel easily. It can rise and fall automatically, by a hydraulic cylinder and the hydraulic system. The coil car can move front or back automatically on two steel rails automatically.

14. Its colors will be painted as per our standard or your requirement.

15. Other optional devices and special requirements can be manufactured for you.

II. Specification parameter

| Model | MT-600H | MT-700H | MT-800H | MT-1000H | MT-1200H | MT-1300H | MT-1600H |

| Metal sheet coil width | 600mm | 700mm | 800mm | 1000mm | 1200mm | 1300mm | 1600mm |

| Metal sheet thickness | 0.1-3.0mm | ||||||

| Coil weight (Heavy duty) | 5000KGS | 5000KGS | 6000KGS | 7000KGS | 8000KGS | 9000KGS | 10000KGS |

| Coil inside diameter | 450-530mm | ||||||

| Coil outside diameter | 1500mm | ||||||

| Decoiling speed | 0-16m/min | ||||||

| Electrical power | 380V, 3 phase, 50HZ (or other) | ||||||

| Motor power | 5HP | 5HP | 7.5HP | 7.5HP | 10HP | 10HP | 12HP |

| Net weight KGS | 1800 | 1900 | 2100 | 2300 | 2400 | 2500 | 3000 |

| Machine size (m) | 1.5×1.2×1.3 | 1.7×1.3×1.4 | 1.8×1.4×1.4 | 2.0×1.5×1.6 | 2.4×1.8×1.8 | 2.5×1.8×1.8 | 3.0×2.0×2.0 |

| Mandrel expanding | hydraulic | ||||||

| Coil pressing device | pneumatic cylinder | ||||||

| Inverter for adjusting speed | included | ||||||

| Coil car for loading coils | optional | ||||||