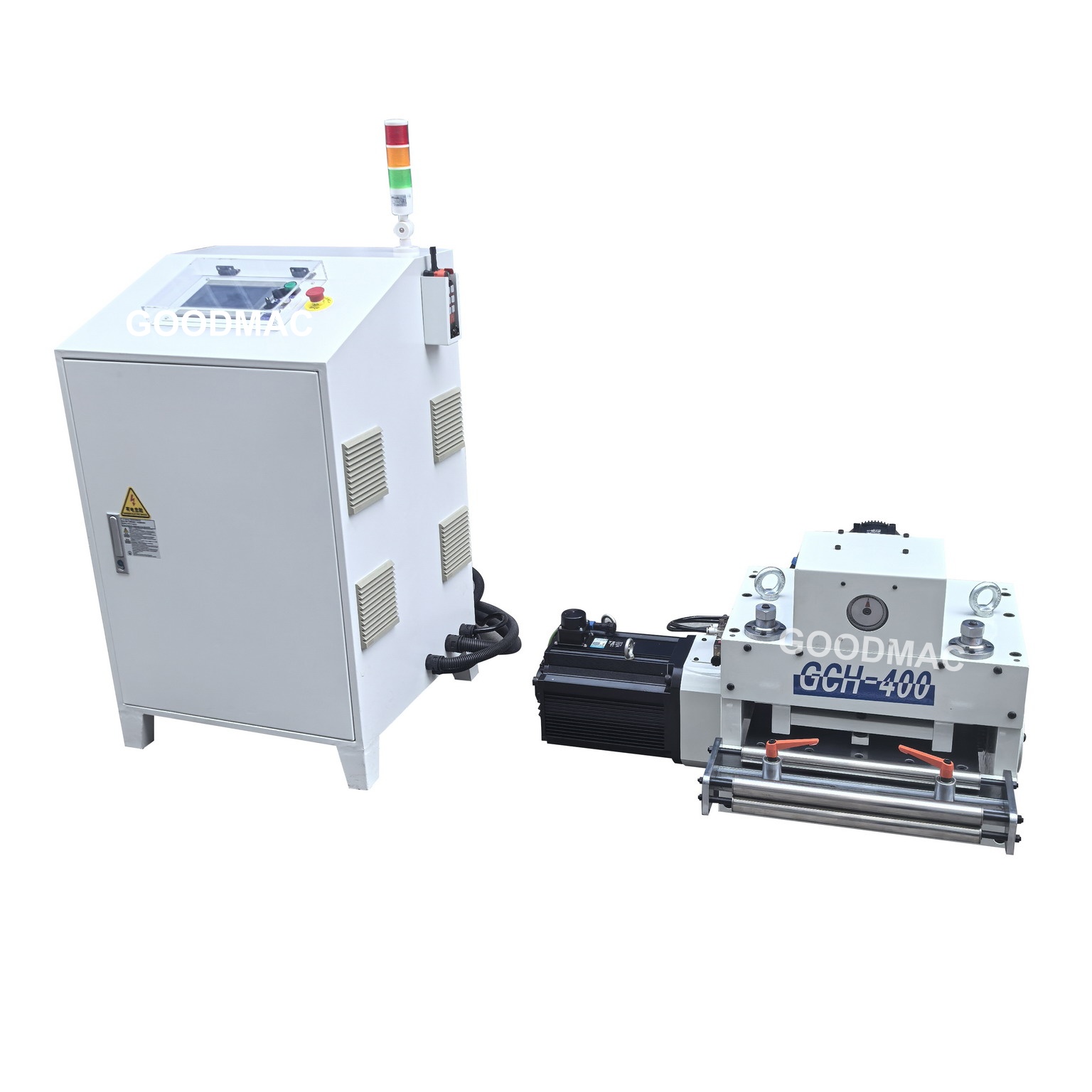

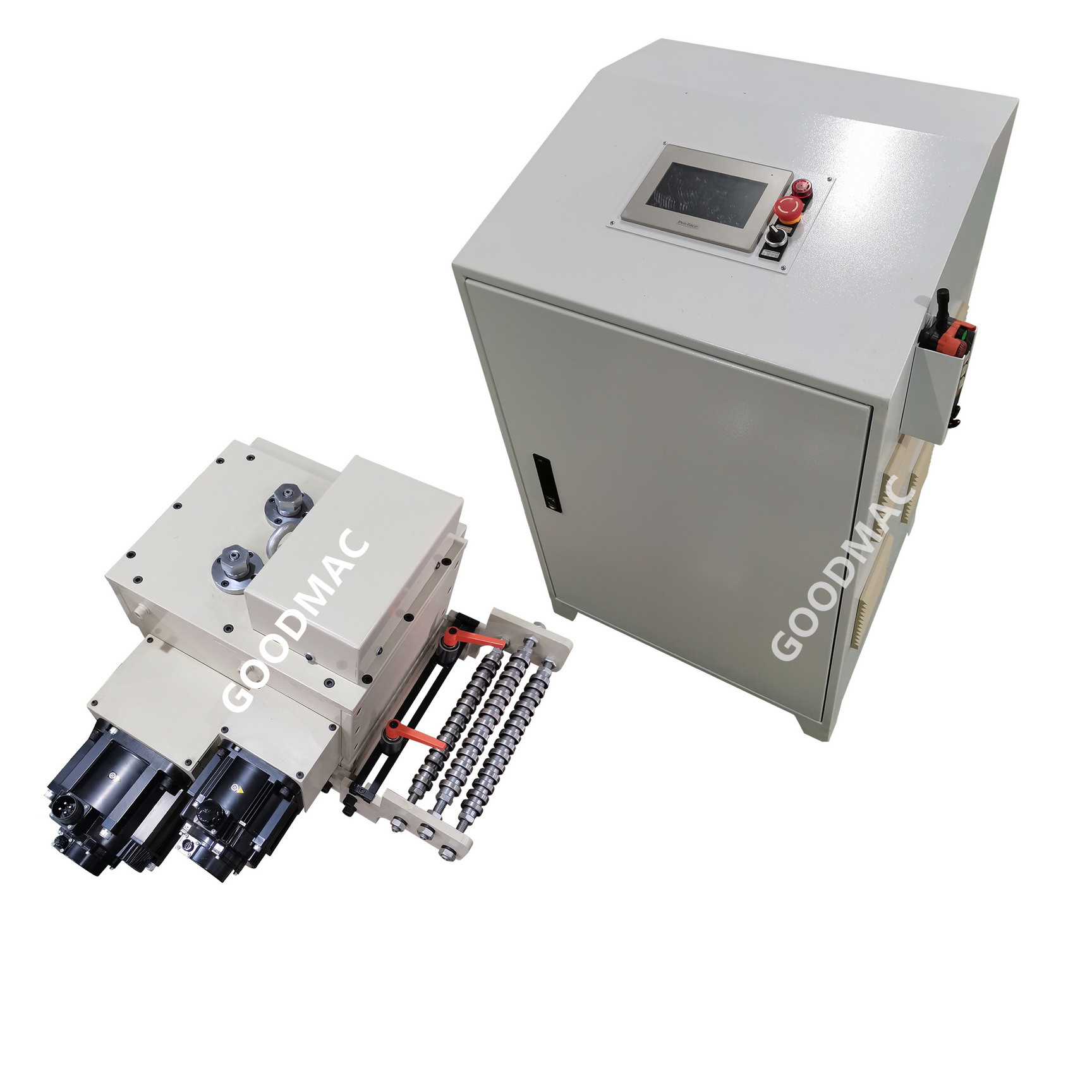

HIGH SPEED NC DOUBLE SERVO ROLL FEEDER, MODEL GCH SERIES

I. Main features

1. These GCH series high speed NC servo roll feeders are very suitable for high speed press machine stamping,

because of high speed feeding and long feeding pitches, to produce electric motor stator and rotor laminations and transformer core laminations efficiently.

2. They can suit for electric steel sheet coil, silicon steel sheet coil etc.

3. A servo motor drives the feeder’s two steel rollers to rotate and feed the steel sheet automatically.

4. A roller can be released through another servo motor drive automatically,

so GCH series feeders are much faster than GCD series feeders.

5. User can touch and input various feeding length at a touch screen panel easily.

II. Specification parameter

| Model | GCH-200 | GCH-300 | GCH-400 | GCH-500 | GCH-600 |

| Metal sheet width | 200mm | 300mm | 400mm | 500mm | 600mm |

| Metal sheet thickness | 0.1-1.6mm | ||||

| Feeding length per stroke | 0.1-9999.99mm | ||||

| Feeding speed | 0-60m/min | ||||

| Electrical power | 380V, 3 phase, 50HZ (or other) | ||||

Servo motor power | 4.4KW | 7.5KW | 11KW | 15KW | |

Servo motor power | 1.3KW | 1.8KW | |||

| Servo motor | YASKAWA | ||||

| Servopack | YASKAWA | ||||

| Encoder | HENGSTLER (or other) | ||||

| Human machine interface | Proface (or other) | ||||

| Pneumatic component | AIRTAC (or other) | ||||