I. Main features

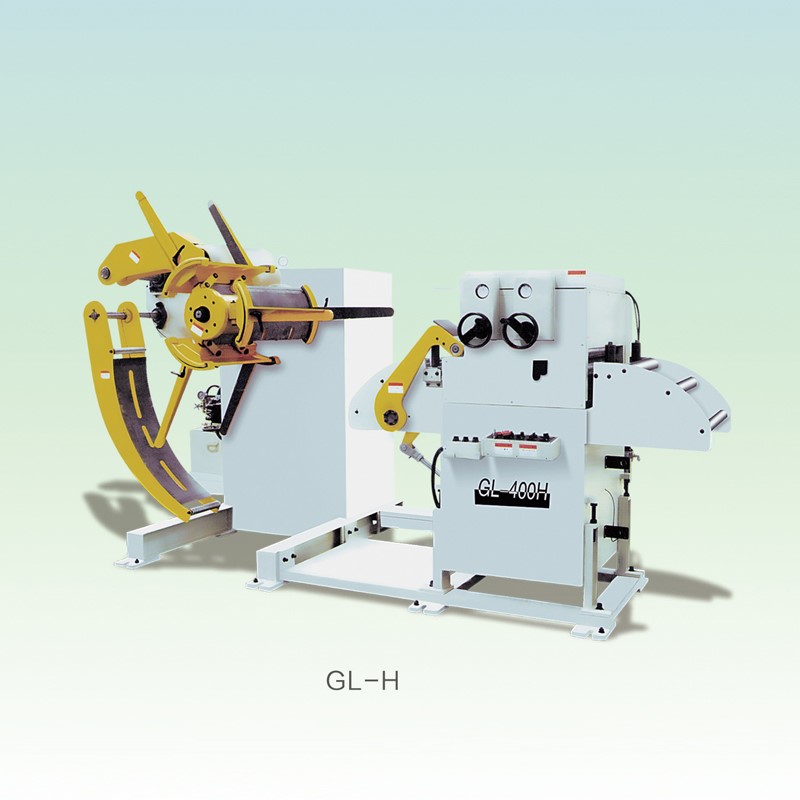

1. These GL-H series machines are very excellent combined decoiling and straightening machines for thick metal sheet coils.

2. They can suit for various metal sheet coil material, such as cold rolled steel, hot rolled steel, galvanized steel etc.

3. With a combined structure design, as 2 in 1, each machine can save workshop space obviously, rather than a separate decoiler and a separate straightener.

4. As a combined machine it can decoil and straighten the metal sheet synchronously.

5. It adopts high quality components, for long service life and low malfunction.

6. Its mandrel expanding adjusting is manual or automatic through a hydraulic cylinder for automatic operation.

7. A pneumatic holding down device is equipped as standard device, to prevent thick metal sheet coil loosing.

8. A supporting device can support the metal sheet to entrance of the straightener throng a pneumatic cylinder drive.

9. Its decoiler has a motor motive, so can decoil the coil through dual row chains transmission automatically.

10. There is an automatic pneumatic disc brake device for the decoiler, so it can stop decoiling smoothly.

11. In beginning of the straightener, there is an automatic guiding device which can guide the metal sheet to its entrance easily.

12. Its straightening rollers are made of high quality steel, with special heat treatment, with high hardness and abrasion performance, for getting perfect straightening performance.

13. With pneumatic cylinders pressure for upper pinching rollers, and worm gear & hand wheel adjustment for upper straightening rollers, this machine can get perfect straightening performance, and is easy to operate it.

14. There is a good electric control box with standard components, so it is operated and protects users’ safety very well.

15. It has an electronic sensor rack, for metal sheet contacting and automatic loop control.

16. A coil car can be equipped as optional device, in order to load a coil to the decoiler mandrel automatically.

17. Some special requirements can be manufactured for you.

II. Specification parameter

| Model | GL-400H | GL-600H | GL-800H | GL-1000H | GL-1300H |

| Metal sheet coil width | 50-400mm | 50-600mm | 50-800mm | 50-1000mm | 50-1300mm |

| Metal sheet thickness | 0.5-4.5mm | ||||

| Coil weight | 2000KGS | 3000KGS | 5000KGS | 8000KGS | 10000KGS |

| Coil inside diameter | 460-540mm | ||||

| Coil outside diameter | 1200mm | ||||

| Straightening speed | 16 m/min | 20 m/min | |||

| Straightening roller diameter | 68mm | ||||

| Straightening roller quantity | 7 pieces | ||||

| Electrical power | 380V, 3 phase, 50HZ (or other) | ||||

| Decoiler mandrel expanding | manaual / hydraulic | ||||

| Coil pressing device | pneumatic cylinder | ||||

| Decoiler motor motorized | standard | ||||

| Rollers gap adjusting | worm gear | ||||

| Inverter for adjusting speed | included | ||||

| Coil car for loading | optional | ||||